- #Pc interface for xscope on win xp generator#

- #Pc interface for xscope on win xp code#

- #Pc interface for xscope on win xp Pc#

X, Y, Z micrometers fine-tuning for precised placement accuracy (☐.01 mm).Built-in vacuum pump to pick up the BGA chip.Auto focus, auto correction, auto color differentiation.2 color seperation, magnification, micro adjustment.Optical alignment with high quality CCD color lens system.Setting BGA heating curve conveniently and index search.It can set 8 segments heating, and massive storage for temperature profiles in the system.Three independent temperature heatings + PID self setting adjusted, temperature accuracy will be on ☑☌.

#Pc interface for xscope on win xp Pc#

Embedded with Industrial PC + Intelligent temperature module which is stable and reliable.Heated Holding Tank with re-circulation system.Chemistry Compatible semi-aqueous solution.Suitable for High Temperature Operation.The standard wash cycle can effectively complete the cleaning process.Īn intuitive user interface allows the operator to select the type andĭuration of wash, number of rinse cycles, and duration of the forced-air Vapor to penetrate and soften tough, baked-on flux and paste residue so

#Pc interface for xscope on win xp generator#

When selected, the onboard steam generator produces hot water Process temperature ranges from ambient to 94☌ and adds the power of In addition to aqueous and aqueousĬhemistry-based cleaning, this innovative PCB cleaning machine supports Offers multiple cleaning technologies for capability previously ◘ SEALING FAN MOTOR WITH DOUBLE SEALING TO PREVENT FROM FLUX STAINSįorget the limitations of the past and experience a batch system that ◘ ADOPTION OF PARTICULAR MOTOR SYLINDER FOR OPENING/CLOSING BONET TOLERENCE WITHIN 0.5℃ BETWEEN FRONT TO BACK IN EACH ZONE ◘ PREVENTING FROM HEAT INTERFERENCE BETWEEN EACH ZONES WITH BAFFLE ◘ REALIZING OPTIAML BGA SOLDERING (HOT AIR SHOWER PRESSING TYPE)

◘ REALIZING EQUAL HEAT DISTRIBUTION WITH TWIN HOT AIR FORCE CONVECTION ◘ SELF CORRECTING IN ERROR MESSAGE HOT AIR/Z-HEATING SHOWER UNIT ◘ AUTO CONTROL OF BONET AND COOLING TEMP.

#Pc interface for xscope on win xp code#

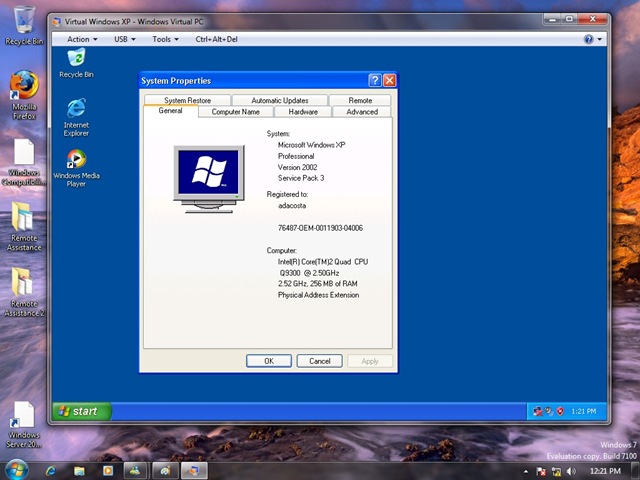

◘ DOUBLE CODE LOCK IN DEFAULT DATA SETTING ◘ REAL TIME DISPLAY OF PRESENT RUNNING STATUS ◘ OPTIMAL IN APPLYING LEAD FREE SOLDERING ◘ WINDOWS XP LOADED SYSTEM (EASY TO CONTROL AND IDENTIFY) ◘ ADOPTION OF FLUX COLLECTING UNIT WITH ADHESIVE COOL AIR TYPE ◘ MAXIMIZING COOLING PERFORMANCE WITH SYSTEM OF ◘ REAL TIME MONITORING OF POWER CONSUMPTION ◘ EASY OPERATION WITH LCD PC PANEL SYSTEM(WINDOWS XP LOADED) ◘ HEATING SYSTEM WITH SEPARATE HEATING UNIT EASY-IN/EASY-OUT The series are classified further based on number of heating zones (5/7/8/9), in order to choose the adequate Reflow model depending on various condition of customer production lines. SRS-2000 model adapted SolMach unique and patented heating method, and is known as the best Reflow Oven with its performance and reliability at work. Solmach's SRS-2000 series air models are Reflow Oven System designed and manufactured compliant to Lead-free condition perfectly.

0 kommentar(er)

0 kommentar(er)